About us

Our Team of experts

Here at Nusbaumer in the cradle of the French glass industry, every employee knows the

importance of manufacturing. Putting their know-how and generations of experience at the service of the customer, this highly specialized industry continues to adapt to new challenges and the most demanding industrial manufacturing methods of today.

We’re part of the “Glass Valley”, the Bresle valley luxury bottles world cluster, an association which was created in 2001 and brings together companies involved in luxury bottles, mainly between Le Tréport and Feuquières in the Oise but also around Dieppe and throughout France.

WE DeLIVER

With more than a century of experience, Nusbaumer continues to pride itself on customer satisfaction in the bespoke moulding industry.

Quality products, a proactive approach, and the fact that old ranges aren’t permanently discontinued are key to this, as is our willingness to adapt to new demands. Nusbaumer continually researches the best solutions to achieve what customers are looking for.

Every year, we invest in new and upgraded high-tech machinery, and to complete each mould to the highest standards, we use: a 5-axis centre MAZAK INTEGREX lathe, a GOM 3D scanner and a laser welding robot).

New investments have been made possible thanks to the upskilling and experience of our employees.

Our mantra: continuous improvement at the service of our customers!

JEROME DESPREZ

Making a mould is a real 'Tour de force' that constantly requires mastering the machine and the operator's expertise. The two go hand in hand! This is why we pay particular attention to training our staff and investing in high-tech machines in order to better meet the needs of our markets.

Alex Leblond

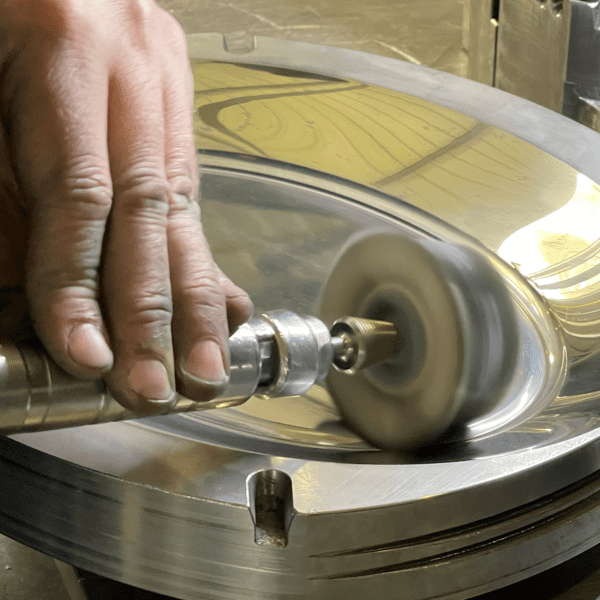

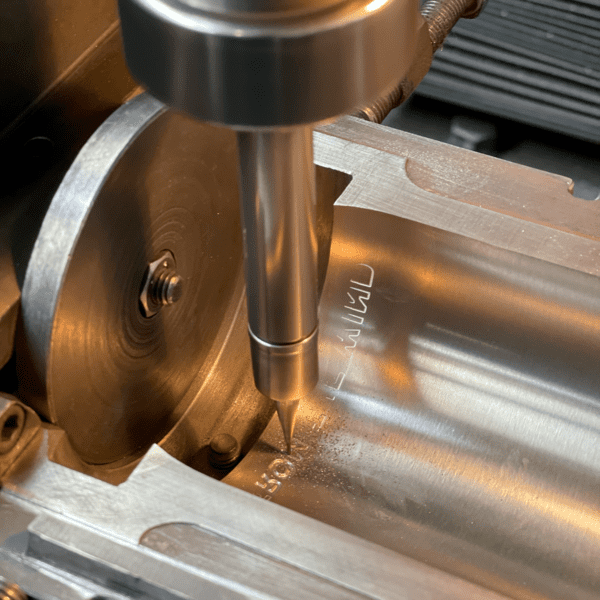

Precision and rigour from start to finish Assembly, adjustment, chiselling, polishing... each of the final stages requires the highest levels of technicity as each team member maintains rigorous precision in finalising the entire manufacturing process thereby presenting the customer with a flawless product. Last but not least , our quality control department ensures and validates the product's conformity before it leaves the workshop.

Our Expertise

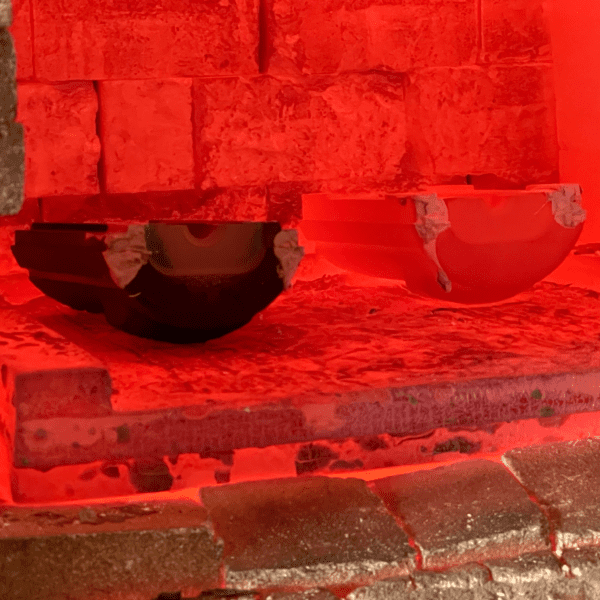

Tenths, hundredths, reverse engineering, scanning, heat treatments, material hardness,

homothety, gull wings, spheroidal, vermicular, Dxf, … all these technical terms are part of the common language

of Nusbaumer sn…

But let’s not forget that the quality of our moulds is made from the hundreds of precise gestures that our highly skilled

colleagues perform in order to create and produce outstanding and exceptional pieces.